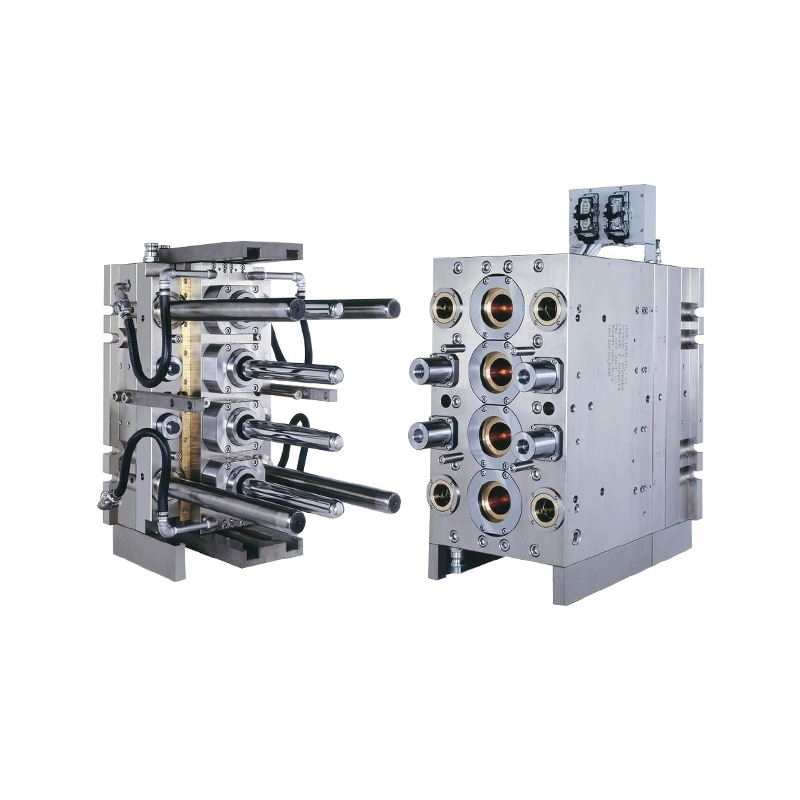

Custom Water Pet Bottle Blanks Mould For Sale Wholesaler Company

The PET (Polyethylene Terephthalate) bottle blanks are a fundamental component in the production of plastic bottles, which are ubiquitous in the packaging industry. These pre-forms are the raw, often tube-like shapes that are later blown and shaped into the familiar bottles we use for beverages, food products, and other consumer goods.

PET bottle blanks serve as the foundational components for PET bottles, crafted from Polyethylene Terephthalate (PET) resin. These blanks undergo stretch blow molding to attain their final bottle shape. Known for their lightweight, durability, and clarity, PET bottle blanks find extensive use in packaging beverages, personal care products, and household items. Their versatility allows for various applications across industries, including beverages, personal care, pharmaceuticals, and food packaging.

The Manufacturing Process of Pet Bottle Blanks:

1. Material Selection: PET is chosen for its strength, lightweight properties, and recyclability. It is a thermoplastic polymer that can be heated and reformed multiple times without significant degradation.

2. Injection Molding: The process begins with the injection of molten PET into a mold, where it takes the shape of a pre-form. This is a highly automated process that ensures precision and consistency in the shape and size of the blanks.

3. Trimming and Cooling: Once the PET has cooled and solidified, the excess material is trimmed away, and the blanks are cooled further to ensure they maintain their shape.

4. Quality Control: Each blank undergoes a series of inspections to ensure they meet the required standards for dimensions, clarity, and freedom from defects.

The Importance of Pet Bottle Blanks in Packaging:

1. Versatility: PET bottle blanks can be blown into various shapes and sizes, making them suitable for a wide range of products, from water and soft drinks to condiments and cosmetics.

2. Barrier Properties: PET provides an excellent barrier to gases and moisture, which is crucial for maintaining the freshness and quality of the contents.

3. Cost-Effectiveness: The production of PET bottles is relatively inexpensive compared to other materials, making it an economically viable option for many businesses.

Environmental Considerations:

1. Recycling: PET is a highly recyclable material, and the use of recycled PET (rPET) in the production of new bottle blanks is increasingly common, contributing to a circular economy.

2. Sustainability: Efforts are being made to improve the sustainability of PET production, including the development of bio-based PET and the reduction of energy consumption in the manufacturing process.

3. Waste Management: Despite its recyclability, PET waste remains a significant environmental issue. Initiatives to improve recycling rates and reduce plastic pollution are essential.

Economic Impact:

1. Job Creation: The PET industry contributes to job creation both in the production of bottle blanks and in the subsequent manufacturing and packaging sectors.

2. Global Trade: PET bottle blanks are traded internationally, fostering global economic connections and contributing to the growth of the plastics industry.

3. Innovation: The demand for PET bottles drives continuous innovation in materials science and manufacturing techniques, pilot to improvements in efficiency and sustainability.

Pet bottle blanks are a critical element in the plastics industry, offering a versatile, cost-effective, and recyclable solution for packaging needs. As the industry evolves, it is essential to continue focusing on sustainability and innovation to small environmental impact while maintaining the benefits that PET bottles provide to consumers and businesses alike.

English

English 中文简体

中文简体