Custom Plastic Pet Bottle Blanks Manufacturing Company

PET bottle blanks stand as a testament to the intricacies of modern engineering and material science, playing a foundational role in the production of ubiquitous PET bottles. While often overshadowed by the final product, understanding the science behind PET bottle blanks unveils a fascinating world of polymer chemistry, manufacturing processes, and structural design.

At the heart of PET bottle blanks lies the polymer polyethylene terephthalate (PET). PET is a thermoplastic polymer known for its exceptional clarity, mechanical strength, and barrier properties. The molecular structure of PET consists of repeating units of ethylene glycol and terephthalic acid, arranged in a linear chain. This unique structure imparts PET with its desirable properties, making it an ideal material for packaging applications.

The journey of a PET bottle begins with the manufacturing of PET preforms, which serve as the foundation for PET bottle blanks. Preforms are typically produced through injection molding, a process that involves melting PET resin pellets and injecting the molten material into a mold cavity under high pressure. The mold imparts the desired shape and dimensions to the preform, which is then cooled and ejected from the mold.

Once the preforms are manufactured, they undergo a process known as stretch-blow molding to transform them into PET bottle blanks. During stretch-blow molding, the preforms are heated to their glass transition temperature and then stretched biaxially using pressurized air. This stretching orientation imparts strength and clarity to the PET material, resulting in bottles with uniform wall thickness and superior mechanical properties.

Temperature and pressure control are critical aspects of the stretch-blow molding process. Heating the preforms to the appropriate temperature ensures proper material flow and facilitates stretching without causing defects such as thinning or necking. Additionally, precise pressure control during the blowing phase ensures uniform expansion of the preform to achieve the desired bottle dimensions and wall thickness.

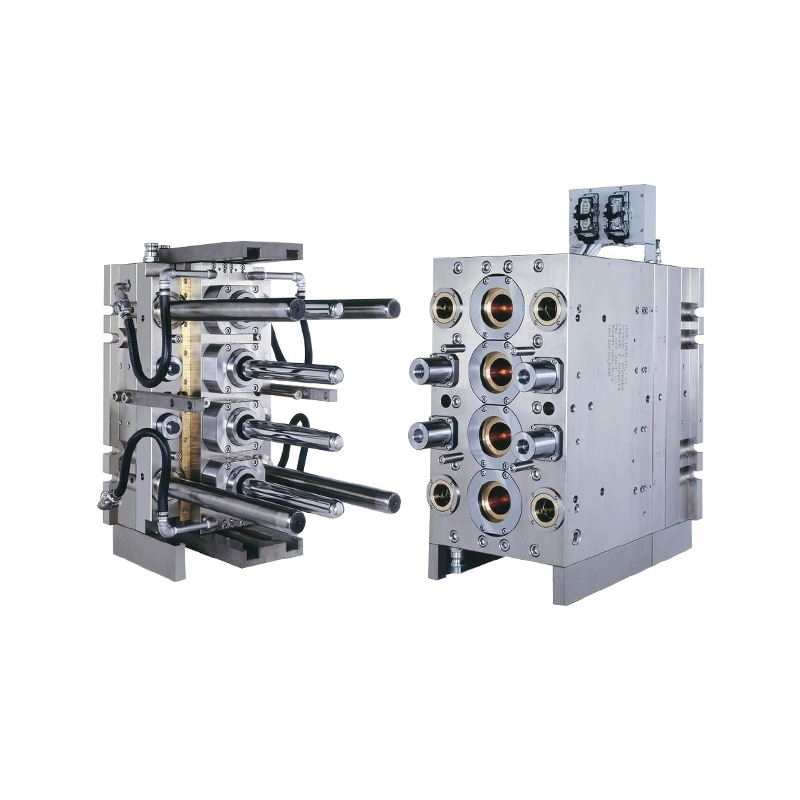

Achieving uniform material distribution and wall thickness is essential for producing high-quality PET bottle blanks. Mold design, process parameters, and material rheology play key roles in ensuring consistent material flow and distribution during the molding process. Advanced mold technologies, such as hot runner systems and multi-cavity molds, enable precise control over material distribution and minimize waste.

Quality assurance is paramount in PET bottle blank production to ensure compliance with stringent quality standards. Automated inspection systems are employed to detect defects such as bubbles, voids, and irregularities in the preforms and blanks. In-line monitoring systems continuously monitor process parameters such as temperature, pressure, and dimensional accuracy to maintain product consistency and integrity.

PET bottle blanks are engineered to meet the structural and performance requirements of various packaging applications. Factors such as bottle geometry, neck finish design, and base configuration are optimized to enhance strength, stability, and functionality. Finite element analysis (FEA) and computer-aided design (CAD) tools are utilized to simulate bottle performance under different loading conditions and optimize design parameters accordingly.

PET bottle blanks can be engineered with barrier coatings or additives to enhance their barrier properties and extend the shelf life of packaged products. Barrier technologies such as oxygen scavengers, light blockers, and flavor barriers help prevent oxidation, light degradation, and flavor migration, ensuring product freshness and quality over time.

Despite their numerous advantages, PET bottle blanks raise environmental concerns due to their reliance on fossil fuels and their potential contribution to plastic pollution. Efforts to mitigate these concerns include increasing the use of recycled PET (rPET) in preform manufacturing, optimizing production processes to reduce energy consumption and waste generation, and promoting recycling and circular economy initiatives.

English

English 中文简体

中文简体