OEM Supply Plastic Pet Bottle Blanks Wholesaler For Sale

PET bottle blanks, often overshadowed by their fully-formed counterparts, are the unsung heroes of the packaging world. While consumers marvel at the final product gracing store shelves, the journey of a PET bottle begins with these unassuming blanks.

PET bottle blanks serve as the backbone of packaging efficiency, streamlining production processes and reducing waste. By starting as compact, uniform preforms, PET bottle blanks optimize storage space and transportation, minimizing logistical challenges and environmental impact. Their standardized form allows for seamless integration into automated manufacturing lines, enhancing overall efficiency and productivity.

Within the realm of packaging design, PET bottle blanks act as a blank canvas for innovation and creativity. Designers and engineers leverage the flexibility of PET to experiment with shapes, sizes, and functionalities, pushing the boundaries of traditional packaging norms. PET bottle blanks enable the realization of innovative designs that cater to evolving consumer preferences and market trends, driving product differentiation and brand recognition.

Contrary to popular belief, PET bottle blanks contribute positively to environmental sustainability efforts. By utilizing lightweight materials and optimizing resource usage, PET bottle blanks minimize carbon footprint throughout the packaging lifecycle. Furthermore, the recyclability of PET ensures that bottle blanks can be repurposed into new packaging, closing the loop on the circular economy and reducing dependence on virgin materials.

In today's globalized market, supply chain resilience is paramount, and PET bottle blanks play a crucial role in ensuring uninterrupted product availability. Their durable yet lightweight composition enhances transportation efficiency, reducing the risk of damage or breakage during transit. Additionally, PET's inert properties safeguard product integrity, assuring manufacturers and consumers alike.

PET bottle blanks offer unparalleled versatility, catering to a wide array of packaging needs across industries. From beverages to personal care products, PET bottle blanks can be customized to accommodate diverse product formulations and packaging requirements. Their adaptability allows for the creation of packaging solutions that optimize shelf space, enhance product visibility, and improve consumer convenience.

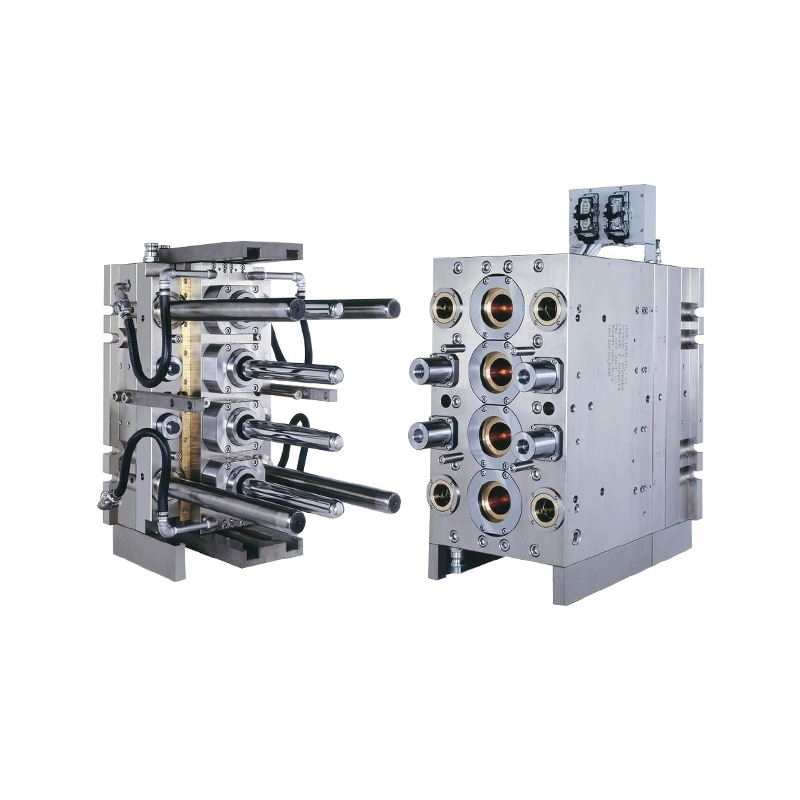

The production of PET bottle blanks drives technological advancements in manufacturing processes and material science. Innovations in blow molding techniques, resin formulations, and recycling technologies continue to enhance the efficiency, performance, and sustainability of PET packaging solutions. PET bottle blanks serve as a catalyst for continuous improvement and innovation within the packaging industry, paving the way for future developments.

PET bottle blanks democratize access to packaging solutions, particularly for small-scale producers and entrepreneurs. Their affordability and ease of customization enable startups and local businesses to enter the market with minimal upfront investment. PET bottle blanks empower entrepreneurs to realize their product visions and compete effectively in an increasingly competitive marketplace.

PET bottle blanks uphold stringent safety and hygiene standards, ensuring the integrity of packaged products and consumer well-being. PET's inert properties prevent chemical interactions that could compromise product quality or pose health risks. Additionally, PET bottle blanks facilitate tamper-evident packaging solutions, enhancing consumer confidence in product authenticity and safety.

The production and utilization of PET bottle blanks foster collaboration and partnership across the packaging supply chain. Manufacturers, suppliers, and brand owners collaborate to optimize packaging designs, streamline production processes, and implement sustainable practices. Through shared knowledge and expertise, stakeholders work together to drive positive change and address challenges facing the packaging industry.

English

English 中文简体

中文简体