Sale Supply Water Pet Bottle Blanks Mould in China Exporter Price

PET (Polyethylene Terephthalate) bottle blanks, a cornerstone of modern packaging solutions, have revolutionized the way beverages, personal care products, and household items are packaged and distributed. Their lightweight, durable, and versatile nature has made them ubiquitous in today's consumer market.

The inception of PET bottle blanks dates back to the mid-20th century when scientists developed PET as a viable material for packaging. Initially used for carbonated beverages, PET bottle blanks gained popularity due to their predominant clarity, shatter resistance, and recyclability compared to traditional packaging materials such as glass and metal. Over the years, advancements in manufacturing techniques and material science have led to the optimization of PET bottle blanks, making them lighter, stronger, and more cost-effective.

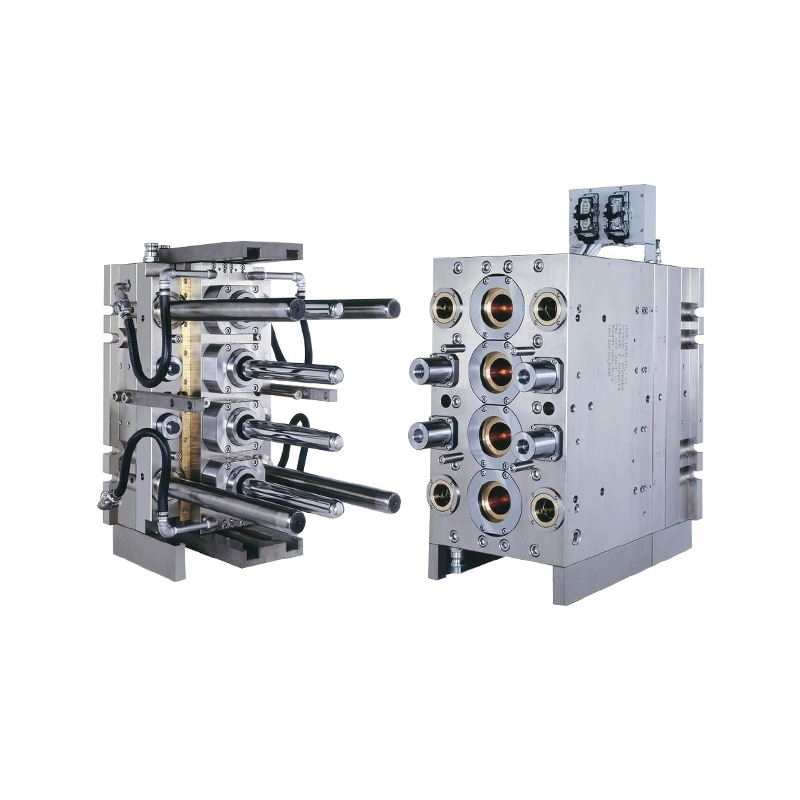

The manufacturing process of PET bottle blanks involves several stages, each crucial for achieving the desired characteristics and performance. It begins with the extrusion of PET resin pellets into preforms, which serve as the starting point for bottle production. These preforms are then heated and stretched using a process called stretch blow molding, where they assume the final shape of the bottle. The entire process is highly automated, ensuring consistency in quality and production efficiency.

Lightweight and Portability: PET bottle blanks are significantly lighter than their glass counterparts, reducing transportation costs and carbon emissions. Their lightweight nature makes them ideal for on-the-go consumption, contributing to convenience for consumers.

Durability and Safety: PET bottle blanks offer excellent resistance to breakage, making them suitable for handling and transportation without the risk of damage. They are also non-reactive, ensuring the integrity and safety of the packaged products, particularly beverages and pharmaceuticals.

Design Flexibility: PET bottle blanks can be molded into various shapes and sizes, allowing for creative packaging designs that enhance brand visibility and consumer appeal. From sleek and smallist designs to intricate shapes, PET bottles offer versatility in product presentation.

Recyclability and Sustainability: PET is one of the more recycled plastics globally, with a well-established recycling infrastructure in many regions. PET bottle blanks can be recycled into a range of products, including new bottles, textiles, and packaging materials, contributing to circular economy initiatives and waste reduction efforts.

While PET bottle blanks offer numerous environmental benefits compared to alternative materials, concerns regarding their environmental impact persist. Key considerations include:

Recycling Infrastructure: Access to adequate recycling infrastructure is crucial for big the environmental benefits of PET bottle blanks. Investments in recycling facilities and education on proper disposal and recycling practices are essential for promoting a circular economy for PET packaging.

Single-Use vs. Reusability: While PET bottles are primarily designed for single-use applications, efforts to promote refillable and reusable packaging solutions can further reduce their environmental footprint. Initiatives such as refill stations and deposit-refund systems incentivize consumers to reuse PET bottles, extending their lifecycle and small waste generation.

Alternative Materials: The development of bio-based and biodegradable alternatives to PET, such as PLA (Polylactic Acid) and PHA (Polyhydroxyalkanoates), presents opportunities to further enhance the sustainability of packaging solutions.

Innovation continues to drive the evolution of PET bottle blanks, with a focus on sustainability, performance, and consumer preferences. Key trends and innovations shaping the future of PET packaging include:

Lightweighting: Continued efforts to optimize bottle design and manufacturing processes for lightweighting, reducing material usage and environmental impact while maintaining product integrity.

Barrier Technologies: Advancements in barrier technologies to enhance the shelf life and freshness of packaged products, particularly for sensitive beverages and perishable goods.

Smart Packaging: Integration of smart packaging technologies such as RFID tags and QR codes for product traceability, authenticity verification, and consumer engagement.

English

English 中文简体

中文简体